3D Printing: A preview into the world of Engineered Healthcare

Introduction

The use of 3D printing in medical science started as a means of developing anatomical study models for surgeons to visualize, practice, and plan their surgeries. Over the course of two decades, however, 3D printing has evolved into being one of the most important technologies in engineered healthcare.

Today, 3D printing is not only used for research and learning, but also to create real-scale anatomical models like guides, stents, custom fit helmets and dressings, and even implants for practical use in the human body.

3D printing is being used to create patient-specific dental implants, prosthetics, hearing aids, bone and tissue replacements, and R&D through surgical guides and medical device prototyping.

In this blog, we talk to Craniovations, the first hospital-based department to be incubated at MSMF-TBI, to gain real-world insights into the use of 3D printing in healthcare. They talk about how they are using 3D printers for equipment and device design, specifically for prototyping and proof of concept modelling.

The Usage of 3D Printers in Healthcare

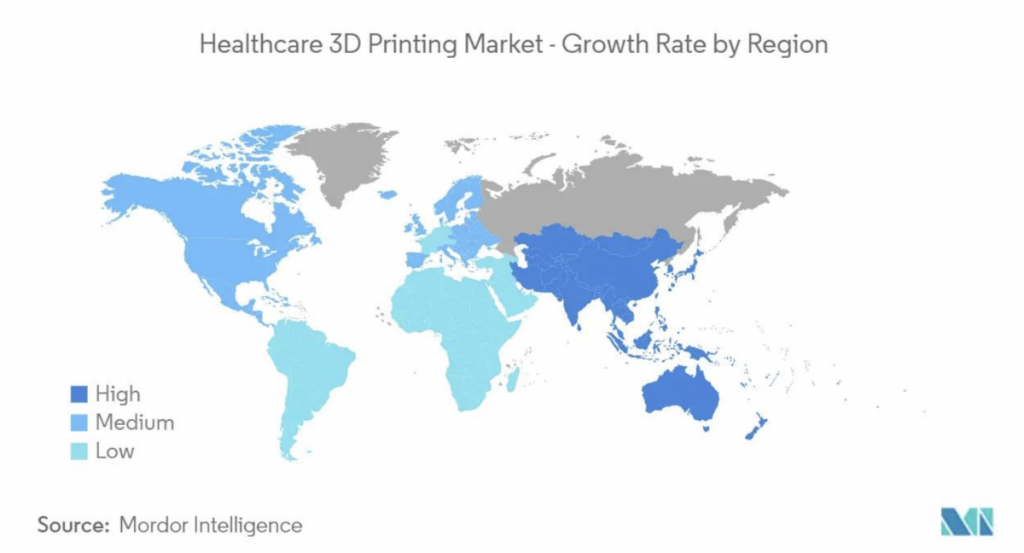

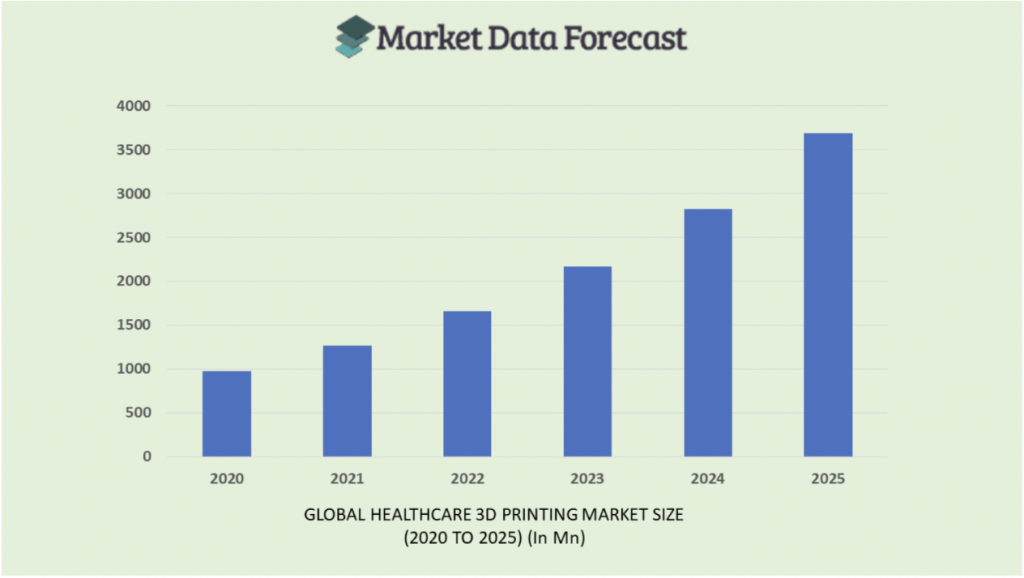

The Indian healthcare 3D printing market is one of the fastest-growing in the world (source)

The team at Craniovations sheds some light on the types of 3D printers that are popular in healthcare technology today.

At MSMF TBI BioNEST, they have access to two types of 3D printers:

- MakerBot METHOD X – Fused deposition modelling (FDM) based 3D printer

- Formlabs 3L – Stereolithography (SLA) 3D printer

FDM 3D printers extrude thermoplastic filaments like Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), and nylon through a heated nozzle, melt the material and then apply the final product layer by layer based on the input design. FDM 3D printers are generally preferred for proof-of-concept models and cost-effective prototyping of simple parts.

SLA 3D printers work with resins like BioMed Amber Resin, IBT Resin, and ceramic resin to deliver the finished product. SLA 3D printers use high-powered lasers to harden stored liquid resin into the desired 3D model. The resulting models have high precision and fine finish making them suitable for building prototypes that require accurate detailing and tight tolerances.

Use Cases

Apollo chain of hospitals implemented in-house 3-D printing labs across seven locations in early 2021 with the aim to use 3D printing to create anatomical models for pre-surgical study and planning, patient-specific cutting and drilling guides, and customized implants and implant moulds.

In 2018, doctors at a governmental dental college in Raipur used 3D printing to conduct a reconstructive surgical procedure on a soldier who was left with a disfigured face after a gunshot wound. The doctors used 3D printing to create a custom cranial implant for the damaged section of the skull and restore the soldier’s facial appearance.

In 2021, doctors at a private hospital in Delhi used 3D printing to restructure the skull of an eighteen-month-old baby born with a rare condition that left her with a triangular-shaped skull. The doctors fed the patient’s 3D CT scan results into the 3D printer to create prototypes of the skull and the upper face. After testing these 3D models, doctors were able to create a surgical plan to restructure the child’s skull without causing any damage to the brain or optic nerve.

Why 3D Printers are Preferred for Prototyping in Healthcare

The primary reason for preferring 3D printers for prototyping in healthcare is definitely to introduce and encourage technological innovation in medicine, says the team at Craniovations. 3D printing is more affordable and accurate today, and there’s no reason why healthcare units should not be leveraging their capabilities.

3D printing is especially useful in prototyping. In medical use cases, there are a lot of design iterations that occur during the early stages of development for any innovative product.

There are generally two key stages that dictate iterations in design. One is during ideation and initial development, when the design is constantly changed and updated based on functional or business needs. The second round of design iterations begins after a working prototype is tested in the real world with actual users. User feedback is studied and incorporated into the design as the product heads towards launch.

The primary contribution of 3D printing in device prototyping is reducing lead time. The time taken to implement design feedback and recreate the new prototype using conventional methods is considerably high. Reducing the time for prototyping then impacts every other process – it reduces costs and the time taken to go to market. Medical device design company Coalesce, for example, used in-house SLA 3D printers to create device prototypes and reduced lead time by 80 – 90% and costs by up to 96%.

Conclusion

Such is the normal design process for most medical or healthcare device development. Performing iterations of this volume using conventional methods of prototyping ends up being expensive and are not feasible for MedTech startups.

Since 3D printing is more affordable and accurate today, it is an affordable option; it is also the more efficient one in terms of precision and time for completion.

3D printing enables innovators to rapidly and accurately improve their prototyping process and arrive at their final working prototypes faster than before.

Subscribe to Newsletter

Recent Posts

- Bridging The Gaps Between Treatment and Diagnosis: The FastSense Approach

- Embedded Finance in Healthcare Industry in India: Collaboration with FinTech and MedTech Companies

- Thermaissance: Where Healthcare and Quality of Life Meet

- Case Study: TeraLumen

- Emerging new business models in the MedTech industry in India